Heat Treat

Tailored Solutions Crafted Precisely For Your Requirements

Heat Treat

Our specialty lies in crafting custom channel induction ceramic furnace linings, meticulously engineered to establish an erosion-resistant barrier between the molten metal and the furnace’s castable lining. By providing this crucial layer of protection, our linings significantly extend the lifespan of your furnace while simultaneously reducing operational costs.

Featured Products

- Hearth Plates

- Rotary Hearth Plates

- Skid Rails

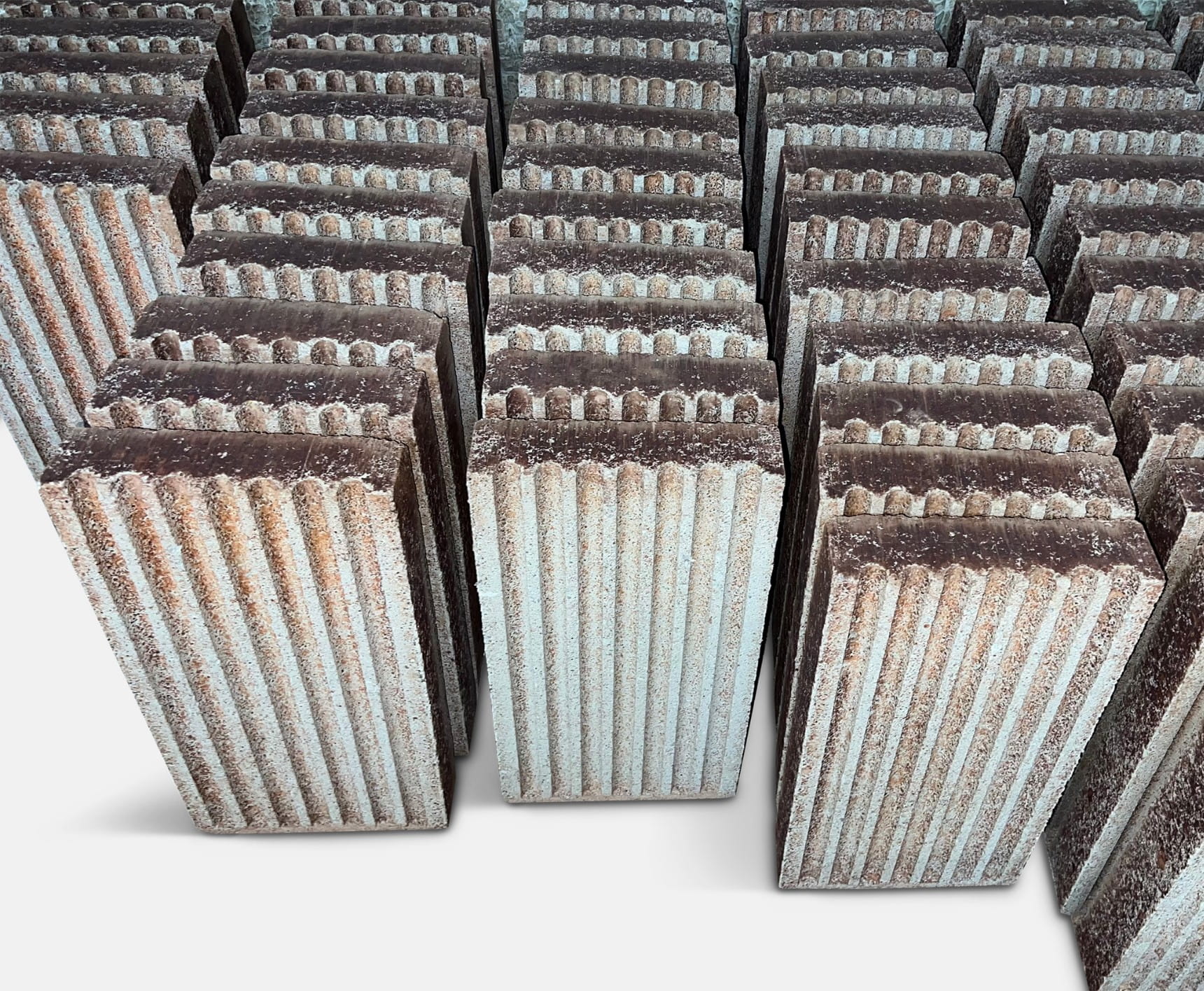

- Pier Blocks

- Jambs

Key Product Features

Leveraging a diverse array of high-quality materials, we employ an advanced forming method that enables us to produce net shape ceramic setters with unparalleled precision. From straightforward one-cavity profiles to intricate multi-level stackable setters, we cater to a broad spectrum of needs, ensuring seamless integration and optimal performance for your specific application.

Nitride Bonded Silicon Carbide: The Ultimate Refractory Solution

Engineered for unrivaled performance in demanding environments, nitride bonded silicon carbide stands as a pinnacle of strength, wear resistance, and oxidation resistance. Primarily designed for applications such as hearth plates, muffles, saggers, and beyond, this advanced refractory material offers unparalleled durability and longevity.

With its exceptional thermal shock resistance, nitride bonded silicon carbide thrives in environments characterized by high temperatures or rapid temperature fluctuations. Its robust composition, resulting from the bonding of silicon nitride and silicon carbide, imparts remarkable hardness, thereby enhancing abrasion resistance and ensuring prolonged service life even under the most abrasive conditions.